Outside the Box Thinking Appreciated, but Not Necessary

With these helpful definitions, understand your custom box inside and out.

Packaging is one of those topics that almost everyone knows a bit about. We certainly receive a lot of boxed items by parcel service these days. And we’ve all boxed up a gift for a holiday or purchased flat boxes to make a move. Beyond those shared events, custom packaging may feel a bit foreign. We understand. But at BoxUp, packaging is what we do and what we have done for the last 30 years. We want to share some of our expertise with you so that you have exactly what you need to make your BoxUp experience a great one.

We focus on turning cardboard into custom branded boxes for anyone to use. Below are a few definitions to help your understanding of the packaging process.

- Box Style: How a box is designed, without regard to its specific size. At BoxUp, our styles are Shipper, Mailer, Gift, Display, Delivery and Gable Box. Each style comes in various sizes. Box Style can also be referred to as box structure.

- Bundle: A small group of unopened, flat boxes put together to be mailed.

- Cardboard: A thin, stiff pasteboard used in the creation of most product packaging including tissue boxes, playing cards and much more.

- Carton: A folded container, also referred to as a folding carton, is a box made of cardboard that is used by consumers for their quantity of product. Cartons are not utilized as shipping containers. An example would be a Chinese takeout container. We do not offer cartons, but the materials we use are much sturdier and are able to be shipped.

- Chipboard: A paperboard generally made from recycled paper stock. Uses include backing sheets for padded writing paper, partitions within boxes and the center ply or plies of solid fiberboard. This is not a material we utilize.

- Corrugated Board, or Corrugated Fiberboard: A type of board that is made of one or more layers of corrugated medium (fluting) and one or more layer of corrugated linerboard. At BoxUp, we use 200# Corrugate board to ensure sturdy, high quality boxes. The 200# refers to the Mullen Test in which the bursting strength is tested and is an industry standard.

- Flaps: Extensions of the side wall panels of the box. These are usually shown on a diagram with a score line and three edges. Some of the flaps are not seen when the box is made, therefore have no print area within our design templates.

- Flute: The wavy layer of medium that is glued between inner and outer sheets of linerboard. This usually runs parallel to the height of the shipping box. Learn more about the types of fluting here.

- Linerboard: The flat sheets of paper that comprise the outer surfaces of a sheet of corrugated board.

- Mullen Test: This test is a standard measure in the packaging industry of the bursting strength of corrugated board.

- Panel: The side of the box.

- Score: An impression made on the box to allow for a fold where the flaps need to be.

- Seam: Where any free edge of a box flap joins another edge. This can be accomplished by using tape, adhesive, stitches or simply closing the container.

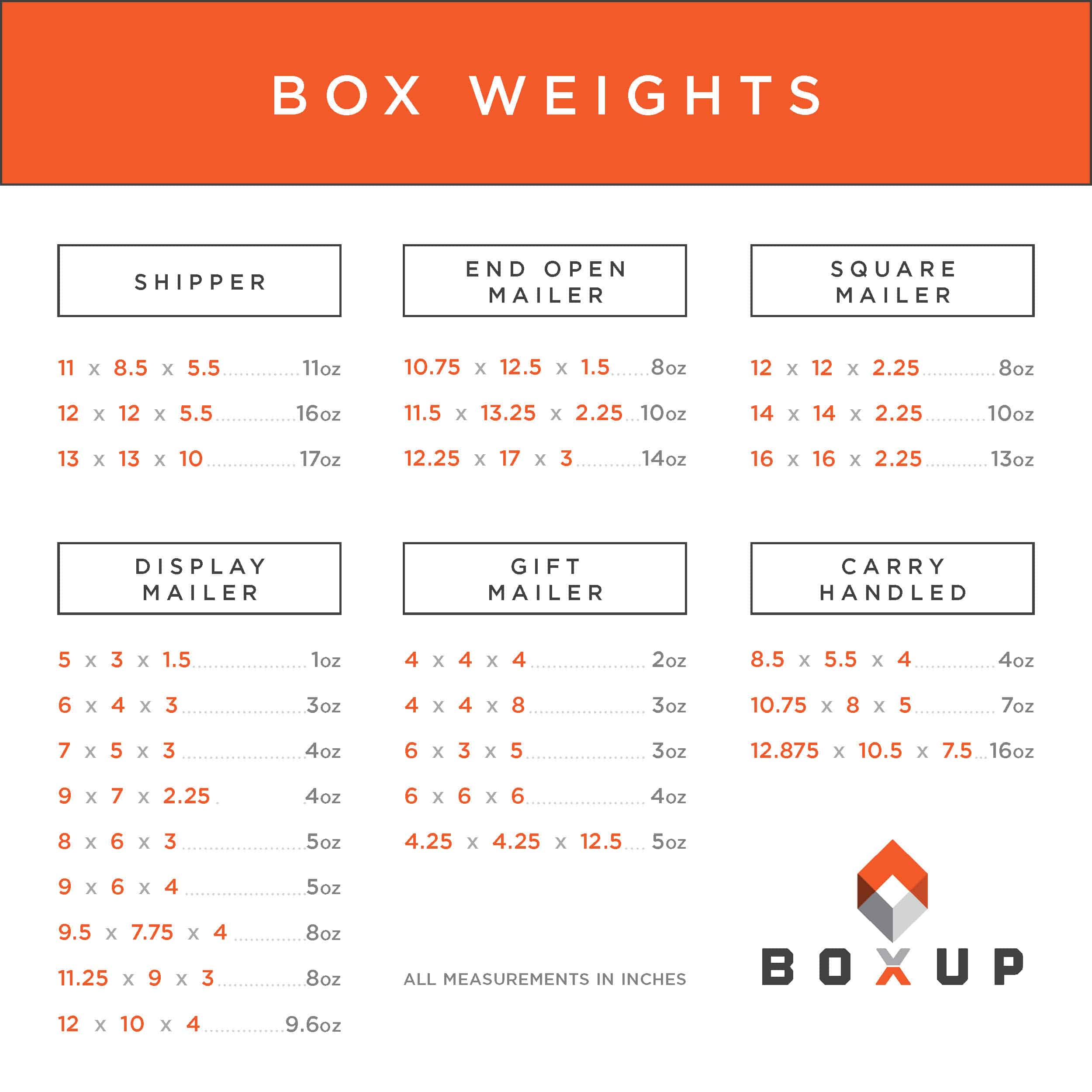

- Tare Weight: The weight of an empty box. Checkout our handy chart with all of our boxes’ tare weight below!

Bonus Definitions for Printing:

- CMYK: Cyan (light blue), Magenta (reddish), Yellow and Black (CMYK) – that’s the key nomenclature of four-color process printing. And that’s what we do at BoxUp with our digitally-printed boxes. We create the many hues and shades of color you see in our gallery of boxes using just these four colors. This means, while your color will always be beautiful, strict Pantone® color matches aren’t possible.

- UV-Cure: Ultraviolet curing is a process where a high-intensity UV light is utilized to instantly cure, or dry, inks and adhesives. BoxUp uses this process to ensure the highest quality look and design.

Still have questions? We are here to help! Contact info@boxup.com.